MEBA3D package

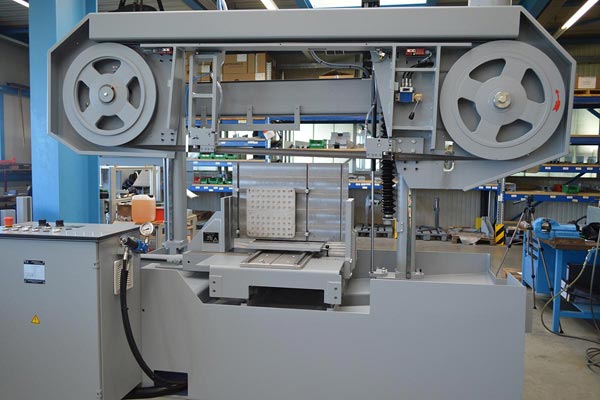

Standard equipment sawing machine

- MEBA High performance package including clamping device

- Saw feed via frequency-controlled ball screw drive with automatic cutting pressure and feed monitoring

➞ Rapid lowering of the saw frame via push buttons - Frequency-controlled AC drive 15-150 m/min

- Hydraulic material full-stroke clamping

- Movable belt guide arm, adjustment to material width

- Precise saw band carbide roller guide

- Rotating chip cleaning brush

- Manual saw band tension with torque wrench

- Coolant device

(can be combined with our MEBA micro dosing system)

MEBAeco 335

| 90° | Ø335mm 500x335mm |

| Motor | 3,0 kW AC |

| Saw blade | 4400x34x1,1 mm |

| Sawblade speed | 15–150 m/min |

| Material weight | max. 250 kg/m |

| Dimensions (LxWxH) | 1200x2150x1900 mm |

| Working height | 750 mm |

| Weight | 1020 kg |

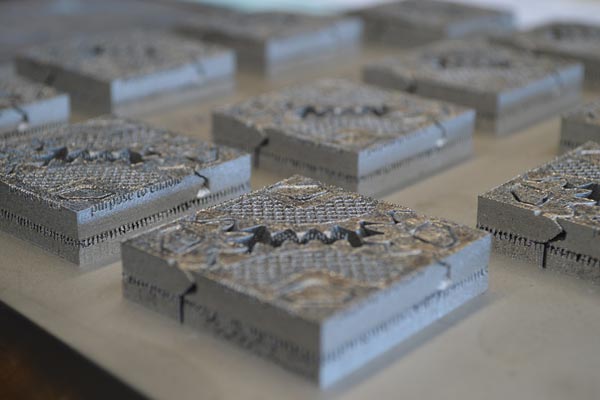

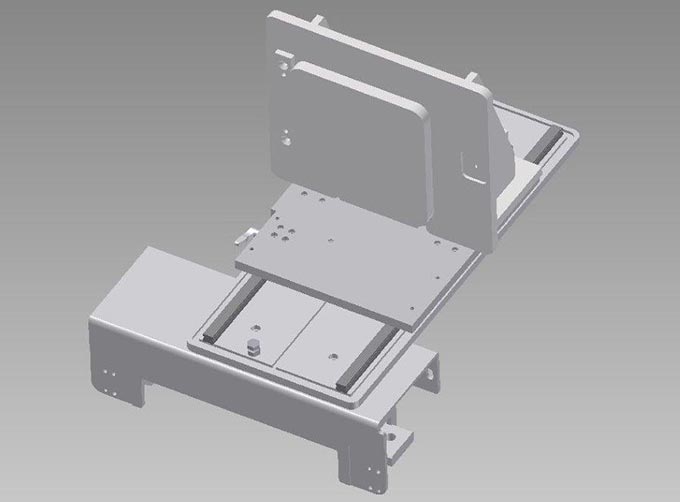

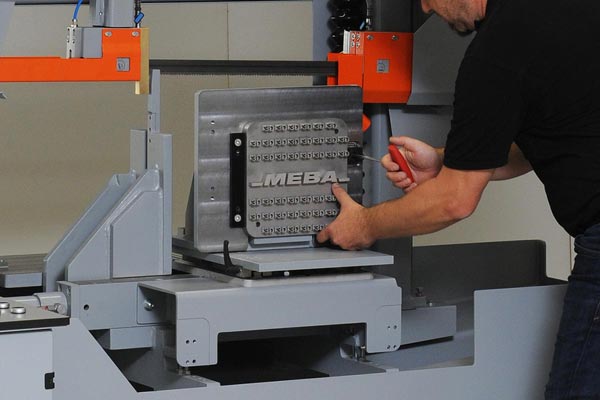

Clamping device for precisely removing 3D printed workpieces

The metal band sawing machine is equipped with a special clamping device and can therefore precisely separate 3D printed pieces from the customer’s mounting plate.

The plate is being attached on the MEBA device which can be accurately aligned due to linear guides.

The fixture plate can be dismantled after the termination of the sawing process, and after a little rework the fixture plate can easily be reused.

Suitable for retrofitting:

The entire device is built on a base plate and can be therefore mounted easily and cost-effectively on already existing sawing machines, completing as a result your machine fleet.

Technical Data

Especially suitable for base plates up to a maximum of:

- max. 300x300 mm

- easily adjustable via linear guides

Your advantages

- High-speed clamping: with one easy movement the base plate can be mounted or dismantled

- Low purchasing costs

- Low maintenance costs

- Few operating steps: clamping, sawing

- Fast process time

- Outstanding cutting results

- Long service life for the band saw blade

- Optimal utilization and amortization: the sawing machine can also be used for standard sawing tasks

- Short changeover time: the entire clamping device can be assembled and dismantled with very little effort in a short amount of time

We recommend further options:

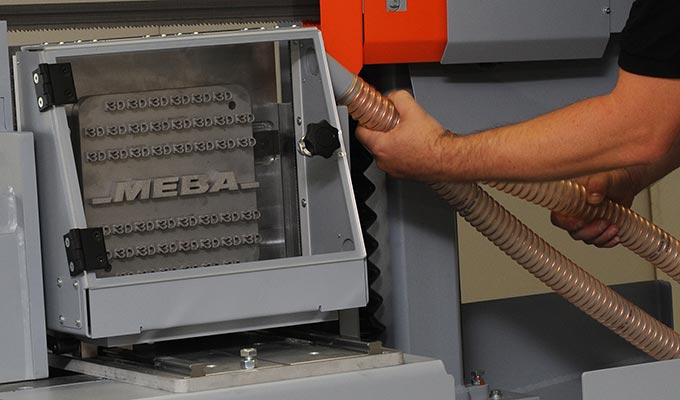

Hood for 3D packageIndustrial Vacuum for the 3D package

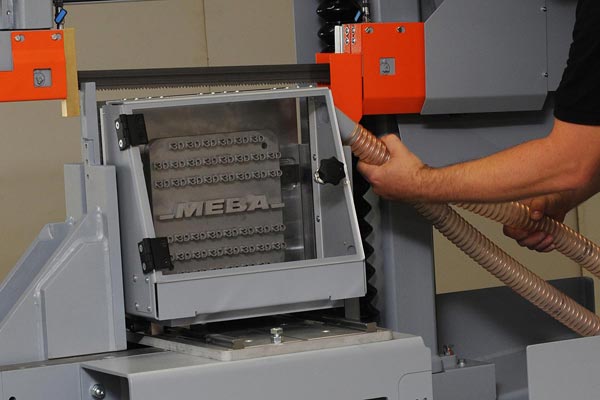

Hood for 3D package

- Enclosed workspace for removing 3D printed parts

- Easy removal of sawn-off parts

- Clean work environment

Your advantages

- Limits the area of dirt

- Removable drip tray

- User-friendly: movable hood for easy attachment and removal of the base plates

- Process reliability: Sight glass provides insight into the ongoing sowing process

- Smooth running: easily movable via linear guides

- Individually adjustable: with the option “suction for 3D package” the machine has a flexible installation of the suction nozzles

- Suitable for subsequent attachment

- Quick and easy assembly and disassembly

Industrial Vacuum for the 3D package

- Industrial vacuum cleaner for the removal of coarse and fine dust

- According to the safety instructions the vacuum cleaner is suited for the suction of combustible and dry dusts in zone 22

- Manufactured according to the guidelines 94/9/EG for equipment and protective systems intended to use in potentially explosive atmospheres

Your Advantages

- For extracting dust during dry sawing

- Clean work environment

- Health protection

- High suction power

- High mobility due to smooth-running castors

- Can be used for all suction tasks and is therefore versatile

Important security indication:

Dust explosion-protected vacuum cleaners are not suitable for the suction of explosive or equivalent substances within the meaning of §1 SprengG. Liquids and mixtures of flammable dusts and liquids are also not suited. The operator needs therefore to guarantee the safe avoidance of ignition sources.

Additive Manufacturing with Metal: How Company “Edelstahl Mechanik” cleanly and economically separates 3D-Printed Metal Parts from the Base Plate

Additive Manufacturing with Metal: How Company “Edelstahl Mechanik” cleanly and economically separates 3D-Printed Metal Parts from the Base Plate